We’ve had three pendants fail on our Steelhead Marine crane aboard our Nordhavn 52 Dirona over the last nine years. The proportional switch proximity sensor is very fragile, but there are other failure points as well. These pendants cost a little less than $1,000 each, so we really needed a longer-lasting and more economical solution. Steelhead does sell a remote control for this crane, but it was sufficiently expensive that we decided to do what we did with our TV lift: adapt a generic remote control system to drive the crane.

The remote control we are using for the TV lift is working well, but the crane is more complex with eight different motions, and its remote also needs to be sealed against weather. We opted for a $550 Kar-Tech Proportional Mini GUIDER wireless remote that we brought back with us to Amsterdam after a recent trip to Seattle. This is the same remote control that is supplied by Steelhead Marine if the wireless pendant option is chosen. We’ll explain how just doing 12 crimped electrical connections is all that is needed to enable a wireless remote for a Steelhead ES-series crane for $610.

|

|

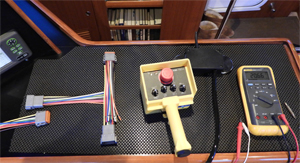

The crane remote control, its base station box (black) and a 12-pin Deutsch connector. |

An accompanying picture (left) shows the remote with its base station. We tested to make sure the assembly was working. Visible at left in the photo are the 12-pin Deutsch connector pigtails that we picked up from Amazon and will eventually use to install the base station for this remote control.

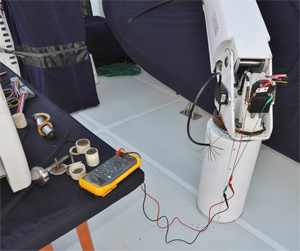

We didn’t have a wiring diagram for the existing crane controls, so the next step was to determine the functionality of each of the 12 wires. We needed to find power, ground, proportional, pump, boom extend/retract, boom swing left/right, boom up/down and line extend/retract. Using a Deutsch pigtail plugged into the pendant control circuit, we probed for each function.

We next mounted the remote control base onto the davit and temporarily wired it in to ensure the remote worked using our findings. This last step was only required because none of the wired pendants were currently working. In the sidebar below, we’ve included the color codes to allow easy installation of this remote control with the Steelhead Marine ES-series cranes without this exploration.

|

|

Testing the remote control base to ensure circuits were properly identified. |

In order to keep the existing pendants working, we planned to build a three-way harness where one end would connect to the wireless remote base, another to the davit control system and the third to the existing wired pendant control.

We determined the wiring for the round pin-based connection on the side of the davit housing where the existing wired pendant attaches.

The next step was to build the three-way harness from two Deutsch pigtails. This allowed both the wired pigtail socket and the wireless remote base station to plug into the crane harness so that either can be used at any time.

|

|

Using heat-shrink tubing to seal spliced connections. |

The only issue we encountered was that the davit housing interfered with the mounting spot for the remote control base, so we moved it around to the other side. We may eventually move the base station down to the circular base where there is more space and less obstruction.

The new remote is a little clumsier to use than the wired remote but, overall, works very well. It’s wonderful to have a wireless remote, and even better to have a cost-effective backup to the delicate hard-wired pendants. We’d disabled proportional control on the hardwired pendants because they always failed, so it was great to have proportional control back.

Spending some time understanding the crane wiring made the problem with one of the wired remotes very clear. We noticed there were only 11 pins in the crane socket, but we knew we needed 12 for full operation. Looking at the socket, we could see the power pin had corroded away. Unfortunately, the remnant of the pin was stuck in our new wired pendant. We used a needle to slowly work the pin to the top of the hole and a small pair of tweezers to remove it.

|

|

The finished three-way harness. |

The corroded pin we removed from the pendant socket was replaced with a new pin (TE Connectivity CPC Series 1) that we installed in the outlet.

Once the pin was replaced in the outlet and the rusted-out pin was removed from the pendant, that pendant worked fine. Our second pendant was found to have a failed fuse, and the third has a broken wire somewhere between the pendant and the connector. If we had nothing else that worked, we probably could make this one work, so we decided to save it.

We now have two functioning wired pendants and a brand-new wireless control, so we feel in pretty good shape for davit control.

|

|

Jennifer using the wireless crane remote control. |

This is an excellent solution for those wishing to add wireless remote operation to the Steelhead Marine ES series of crane. You will need these parts:

• Kar-Tech Proportional Mini GUIDER system: $550

• (2) Deutsch pigtails: $30 each

That’s all that we needed to do this installation. The Kar-Tech remote base station is equipped with magnets that allow it to be stuck to the crane. You need to do 12 crimped wire connections using the color code data and, once done, just plug it in and enjoy remote crane operation.

James and Jennifer Hamilton power voyage aboard their Nordhavn 52, Dirona. Their blog is mvdirona.com.