To the editor: Navigating the seas is a matter of time. You need a clock. Indeed the GPS satellites we use today are just elements of one big complicated clock.

Until the middle of the 18th century, navigation was strictly limited to the calculation of latitude. The determination of longitude at sea was but a dream because the motions of the stars were poorly understood and the only accurate time machines were land-bound pendulum clocks.

In 1994 my good friend Tim gave me a book for my birthday. He had no idea what it would do to me. It was Dava Sobel’s Longitude the compelling story of John Harrison, an English carpenter, who invented four clocks capable of sailing the seas. Over nearly a lifetime he built the sea clocks now named H1 through H4. The first three are large machines each weighting up to 80 pounds. The last, H4, is an overgrown pocket watch. Parliament had offered a fortune to anyone who could determine longitude at sea. In 1761 and 1763 Harrison’s H4 did it on two trans-Atlantic voyages, first carrying longitude to within one nautical mile error and then to nine nautical miles. Parliament ultimately gave Harrison the prize for this astonishing accomplishment and Capt. James Cook mapped the world with it. What is truly surprising is that these sea clocks all still exist, ticking away in the National Maritime Museum in Greenwich, England. When I read Sobel’s book, I decided I was going to build a replica of the Harrison sea clocks.

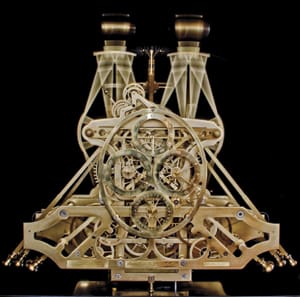

Of the four sea clocks, H1 has the most outrageous appearance. It’s made of wood and brass, weighs more than 70 pounds and is about three feet across. It has four counterbalances hanging randomly from each side with brass finials that look like they were stolen from the curtain rods in Harrison’s living room. And there are two large brass dumbbell balances that slowly swing back and forth beating off the seconds. Indeed it was love at first sight.

H1 had another attraction for me. It had already been replicated by a model builder named Leonard Salzer, and his design was so good that some years after his death his replica sold for nearly one million dollars. Through a bit of luck and perhaps an oversight on the part of the National Maritime Museum, they sold me a partial set of Salzer’s drawings. Those drawings got me started on the design of my replica.

There are more than 1,400 parts in H1, and just trying to understand their individual functions is daunting. The basic machine is what engineers call a nonlinear oscillator, meaning it is capable of some pretty bizarre behavior. It is all part of the legacy of being Harrison’s first machine. After years of collecting information, it took about six months to create a 3D design of the clock.

The next step was to buy the metal and machine the parts. My father was a tool and die maker and while I was still in school I served as his apprentice. I picked up enough from him to get me through.

Clockmakers say that their machines do not run, they go, and mine started going about eight months later. I have made use of modern screws to assemble the frames, but otherwise the machine is true to Harrison’s 18th century technology. It has no bearings and requires no lubrication except on the large steel power springs. Instead this mechanism employs natural, oil-impregnated bushings made from the greasy heartwood of lignum vitae, also called ironwood. It has Harrison’s famous grasshopper escapement, and it must be wound once a day.

I’m now at the stage where, as a clockmaker would say, “I need to bring the machine to time.” Indeed Harrison’s biggest challenge, besides getting the sea clock to operate on a rolling ship, was temperature compensation. Any brass clock employing steel balance springs will lose time as the temperature rises. That’s because the clock parts expand and the springs weaken. Without any mechanism to compensate for these effects the clock will lose about eight seconds per day for every degree Fahrenheit increase. For a ship at the equator that represents two nautical miles error in longitude per day per degree temperature change.

Harrison solved this problem by inventing the bimetallic strip, which are still used today in household thermostats to regulate the temperatures in our homes. But Harrison used them to increase the stiffness of the clock’s balance springs as the temperature increased and thereby regulated the clock rate.

In the end, Harrison’s greatest achievement was to prove that it could be done, that with a clock ticking away below the decks of a tall ship he could measure time with sufficient accuracy to determine longitude at sea. Eighteen years after reading Sobel’s book and 250 years after Harrison’s sea clock carried longitude from the Old World to the New I am looking to the next phase of my adventure, to board a ship, a tall ship, and carry longitude back across the Atlantic.

—————-

Douglas Drumheller has bachelor and masters degrees in mechanical engineering from the USC, and a PhD in applied mechanics from Lehigh University. He has written two college textbooks on wave theory and holds 11 U.S. patents in acoustics. He worked at Bell Labs and Sandia National Labs. He currently lives in New Mexico.