The first blocks used a simple wheel turning on an axle. Then clever hardware guys like Peter and Olaf Harken used slippery and lightweight plastic ball bearings in blocks for race boats. Now Ino-Rope, a company in Concarneau, France, has developed a product called Ino-Block that uses a Dyneema strop for its load bearing and turning element, a patented approach called Textile Axle Technology (TAT). Intended as a high-tech lightweight block for race boats, the simplicity of the TAT Ino-Block and its ease of servicing make it a potentially attractive approach for voyaging sailors.

Founded in 2013 by sailor Thibault Reinhart, an experienced offshore racer in the Mini Transat 650, and rigger Julien Barnet, Ino-Rope is “focused on new technology and extending the range of sailing and industrial blocks.” Barnet and Reinhart conceived of the Ino-Block, and took two years to develop and test versions of it before real-life testing on board the IMOCA 60 race boat Banque Populaire on the Transat Jacques Vabre Race in October 2015. The Ino-Block product was released in 2015 and was nominated for a DAME design award at the 2015 METS marine show in Amsterdam. Ino-Rope currently offers a range of eight Ino-Block models from 0.8 to 6 tons working load.

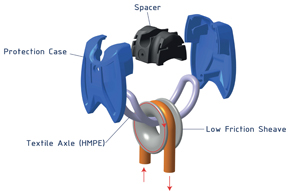

The block is composed of only five elements: an aluminum sheave, a Dyneema strop that acts as the soft axle of the block, a plastic bridge piece the strop is wrapped around and two plastic cheeks that enclose the unit from the sides. Looking at the exploded view it seems counterintuitive that the Dyneema strop would allow the sheave to turn smoothly without binding. According to Etienne Fournier, an engineer at Ino-Rope, the unit works due to several factors. “The concept is really simple,” Fournier wrote in an email. “A sheave turns around a textile axle. The Dyneema has a low fiction coefficient … and the sheaves are made from aluminum with a special treatment with a low friction coefficient, which provides really good efficiency to the system.”

Even more surprising, perhaps, is that, according to Fournier, the block’s friction level drops as increasing load is applied. “At higher load the Dyneema gets more and more smooth like a mirror and friction decreases.”

Another apparent plus of the Ino-Block is its low maintenance requirements. “We use the term ‘maintenance free’,” wrote Fournier, “because the user does not need to add lubricants to the system in order to make it function.” One component of the Ino-Block that does need attention, however, is the Dyneema strop. “The long-term maintenance is fixed at one year. After this period we advise the user to check the state of the loop. The user can send us a photo of the loop and we are able to tell if it’s okay or if a replacement is needed. We currently guarantee one year of use and 10,000 miles. But we are thinking of extending this guarantee according to the good state of the blocks that came back from Banque Populaire.”

|

|

The block’s five elements: spacer, two-piece case, strop and aluminum sheave. Orange is the running line. |

Since the other parts of the block are aluminum and plastic, they don’t need replacement. One potential problem might be UV degradation of the cheek pieces since they receive the bulk of sun exposure. So far, according to Fournier, that has not been a problem for the test blocks.

Ino-Rope is working on new block configurations that could conceivably be used all over a boat in various applications. “This is the kind of block that can replace almost all of classic blocks,” Fournier wrote. “We are thinking about integrating a cleat, double and triple block, a foot block.”

Ino-Blocks are available now by going to Upffront.com, a website that, according to Phil Anniss of Upffront, “represents an all-new model for distribution of sailing hardware and rigging systems, worldwide, via the Internet. This enables small niche manufacturers, like our friends at Ino-Ropes with a really cool new product, to reach a bigger audience, quicker … to help them recover their significant R&D investment.”

One possible drawback to Ino-Blocks for the average cruising sailor might be cost. Voyagers looking to replace an average-sized block, could choose an Ino-Block 3.6, which has a sheave diameter of 46 mm (1.81 inches) and a list price of $192, while, for comparison, a Harken 57 mm (2.24 inches) swivel aluminum Cruising ESP block is list priced at $99.

For the present, Ino-Blocks may be a little too cutting edge for most voyagers. If this type of block technology becomes more widely used, however, it will be intriguing to see if it starts finding its way aboard voyaging boats.