Brian Russell is a capable man. For the last 30 years, he has worked as a sculptor, blacksmith, welder, machinist, glass caster and woodworker. Now he is building a 43-foot aluminum pilothouse cutter on his property in Tennessee.

For as long as Russell can remember, he has been a sailor and drawn to all things marine. He learned to sail from his father and in the 1990s built himself a Herreshoff Biscayne Bay 14. As his sailing experience grew, so did his desire to build a substantial yacht capable of ocean voyaging — an expedition boat if you will.

As an experienced metal worker, it was natural that he was drawn to working in that media. Russell embarked on a self-study course in boat design and was taken in by the work of South African naval architect Dudley Dix whose steel and aluminum boats are world-renowned for their seaworthy design as well as offshore performance.

|

|

The Oddyssey 43 at an early stage of construction. |

“For several years I looked at plans, visited boatyards and absorbed knowledge, trying to separate fact from opinion — a tricky thing,” Russell said. “Boat design isn’t strictly engineering, of course. The sweep of a lovely sheer is art, as is the way the bottom plates transition into the stem. Dudley Dix’s designs have very good engineering numbers; the various coefficients of this and that, which he readily provides, indicate a seaworthy design with good sailing characteristics.”

Speedy and maneuverable

“Dudley likes to go fast,” Russell continued, “but he also understands that cruising isn’t racing. Maneuverability, or lack thereof, is a safety issue, so a moderate fin keel and massively built spade rudder [editor’s note: the design calls for a 4.5-inch diameter shaft] of proper chord depth that doesn’t easily stall can enhance the boat’s safety. Not all spade rudders are skinny little things! When one does the research and understands the design principles, Dix’s design choices really begin to make sense and stand out from the alternatives. And his boats are buildable, especially with the cutting files created by Alumar Yachts [a Swiss firm]. The radius bilge technique, first introduced by Ted Brewer in the 1970s, is a very builder-friendly method of producing a remarkably fair hull that is much more aesthetically pleasing, to my eye, than a multichine hull.”

|

|

Plating almost completed. |

Russell began building his Dix 43 pilothouse cutter, Odyssey, and established Odyssey Yachts, which now can provide pre-cut kits in aluminum, based on the CAD cutting files engineered by Alumar Yachts, for boats designed by Dudley Dix.

The hull shape of the Dix 43 pilothouse sloop departs as far as possible from the boxy styling of some metal boats. According to Dix, “The hull shape has a radius chine round bilge, with long waterline and clean underbody. The long waterline increases the load carrying ability, reduces the canoe body depth and fines up the entry for wave penetration. The stern is fairly beamy with a flat run to give a clean and flat wake, with resultant ease of control off the wind. The overall result is a reduction in wave-making both fore and aft, and improved speed through the water. A conical stem plate is used to increase flare in the bows, providing more reserve buoyancy and dryness to windward.”

Power to push through rough conditions

Keel options for the Dix 43 are fin or shallow draft wing. The rudder is protected by a full skeg. The yacht has a long waterline to carry the yacht’s structural weight with a displacement/length ratio of 238. With a sail area (main plus 100 percent fore-triangle) of 975.6 square feet, it has a sail area/wetted surface ratio of 1.94 (or 2.43 with main and genoa). These factors all result in a boat that has the power to push through rough conditions and the ability to keep moving in the light air.

|

|

Russell welding hull plates. |

Below decks, there are berths for six in three cabins. There is only one head as a way to keep the plumbing simple. The U-shaped galley has been positioned forward of the nav station to starboard. This arrangement gets it out of the main traffic area of the pilothouse and allows for large reefers, freezers and storage lockers. The stove is a Dickinson Mediterranean model. The sinks are positioned on the centerline to facilitate drainage underway. There is a Cruise 40 gph watermaker. Refrigeration is by SeaFrost. Climate control includes a Flagship Marine FM-20 air conditioning system.

The pilothouse has a raised dinette with folding leaves to seat eight. An island seat on the centerline is located over the engine and can be removed in one piece for machinery access. There is also inside steering at the nav station.

|

|

The fully-plated hull. |

Another unique feature is a large lazarette that is accessed by removing the companionway steps rather than a cockpit hatch.

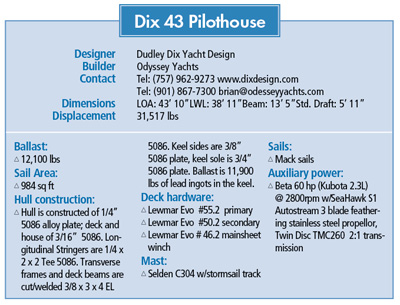

The rig is large and is set up as a cutter. It is equipped with a Selden mast Model C304 with a storm sail track, Selden B200 boom with slab reefing, Sta-Lok lower fitting with swaged uppers, Mack sails, and a Pro-Furl jib furler. All sailing hardware is Garhauer or Spinlock. Deck equipment includes Lewmar Evo 55.2 primary winches, 50.2 secondary winches, and 45.2 mainsheet winch. The steering is via a Jefa RG10-50, 1:5 reduction gearbox. The vessel will also be equipped with an autopilot.

|

|

The Odyssey 43 after the hull was turned upright. |

Auxiliary power is provided by a Kubota 2.3 Liter Beta 60 marine diesel with Twin Disc TMC260 2:1 reduction gears. The propeller is a SeaHawk S1 Autostream 3-blade stainless steel feathering prop. For electrical power there is a Beta D1105 9kW genset and Victron Multiplus 12/3000 inverter. Battery banks are made up of a 980-amp-hour house battery bank, an Optima start battery and an Optima genset start battery.

Once completed, Russell’s Odyssey/Dix 43 pilothouse cutter promises to be a sturdy, “go anywhere” world-class cruising yacht finished to an impressive standard. It will stand as testimony not only to Dix’s legendary design work but also to Russell’s skill as a builder.

|