Most cruisers I know dutifully change their mineral engine oil every 100 to 150 engine hours as per the manufacturer’s recommendations. A few have told me that they stretch that out to as much as 250 hours, especially if they have more modern engines. These relatively frequent changes can involve a lot of oil if the engine — like my old 60-hp Perkins 4154 on my previous boat — holds about eight quarts. If you happen to own a big diesel-powered truck, you could be using much more than that in a year’s time. And just imagine what a whole fleet of trucks or boats would use!

Changing oil on a boat’s diesel engine can be a time-consuming, messy job. In order to simplify matters, I have fitted a brass nipple and hose to the bottom of the oil sump on my current Yanmar engines so that I can draw all the used oil out easily with a hand pump when necessary. The standard Yanmar method is to draw it out through the dipstick hole. Now that is really a pain in the neck, and a laborious process. And in an aft-angled engine, it doesn’t get to all the oil in the bottom of the sump. Some use a small 12-volt pump or a relatively expensive commercial setup with an Integral pump and dump bucket. Personally, I prefer the simplicity of using a small manual pump, but then again I only have two and a half liters to remove from each of my small Yanmar engines.

Then there is the problem of where to dispose of the used oil. In the U.S. it is not much of a problem, as many service stations will take it. But overseas in Third World countries, few places have a proper oil disposal method, and it can be difficult to dispose of it responsibly. Sometimes island locals burn it or otherwise use the oil for various purposes. Also, suitable lube oil for diesel engines is not available everywhere overseas, and it’s often expensive.

Major concerns

There are several things we need to be concerned about with the lubrication oil in our diesel engines. This includes:

1. Small solid contaminants, wear particles, dirt, etc., especially those in the 5- to 15-micron range, cause internal abrasion and wear mostly during engine start-up.

2. Soot, sludge, oxide insolubles and glycol compounds create deposit formation, leading to more wear and combustion inefficiency.

3. Water contamination allows the formation of acids that can corrode metals.

4. Oil lubricity, even with synthetics, degrades over time.

5. Fuel dilution degrades oil lubricity.

6. Important additives need periodic replenishment.

By changing all the oil as recommended, you cure most of the above issues for a short time. But what about the period between changes? The wear particles, much smaller than those even the best full-flow filter can remove, are still running around your engine. And any soot and water contamination is doing the same. No filter can remove fuels from oil, but this should not be a problem with a properly adjusted and tuned engine. Additives are replenished with an oil change or even by adding a small amount of new oil.

Regarding lubricity, this is from the independent Machinery Lubrication magazine: “There’s an old saying that oil doesn’t wear out; it just gets dirty. Although there is some validity to the idea that dirtier oil will ‘age’ quicker than clean oil, the engine oil will have a finite life. It will need to be changed eventually no matter how clean you keep it.” But lubricity can certainly be improved over the long term by using synthetic oils.

|

|

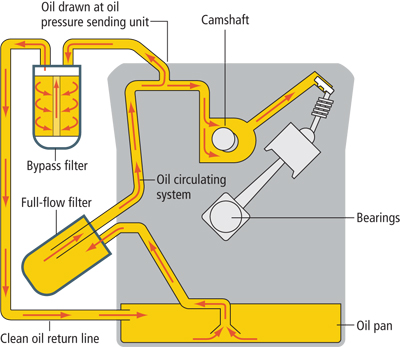

A bypass oil filter is used to clean engine oil using finer filter elements than would be possible in the standard filter. This results in cleaner oil and less wear on the engine. |

However, there is another way to prevent most of these issues that is better for your engine while reducing the oil usage and expense.

It is known as bypass oil filtration. It involves taking about 5 to 10 percent of the oil at a time off on a separate bypass route to run through a very fine filter while the full-flow filter maintains full oil pressure with the rest of the oil passing through it. A bypass filter is capable of removing extremely small-sized particles from the oil by providing in-depth filtration through a densely packed filtering media. Bypass filtration can filter out particles of less than 1 micron, while the best full-flow filters generally filter at no less than about 10 microns, but often at 30 to 40 microns, in order to maintain full-flow oil pressure.

Diesel truck fleets have been using bypass oil filtration, synthetic oils and greatly extended oil change intervals for years at huge savings for their owners. Many companies, including Amsoil, Jackmaster, Gulf Coast, Frantz, Kleenoil, Triple R and others, sell bypass oil filtration units now. Many websites describe in detail the process technology and how it has improved during the past 60 years. There is also a great deal of independent information regarding research and benefits on the Internet now, including this from Machinery Lubrication magazine: “In a case study performed by General Motors and published by the Society of Automotive Engineers (SAE), it was determined that engine service life could be extended eight times when 5-micron filtration is implemented versus the standard 40-micron filtration.”

And this from Blackstone Labs, a well-regarded, independent oil testing lab: “Having run many tens of thousands of diesel engine oil samples, it is our opinion that a bypass oil filtration system is one of the most important factors in extending oil drains. We have analyzed oils which have been in service on diesel trucks for 240,000 miles and found nothing unusual in the analysis.”

Personally, I have used synthetic oil with the U.S. Amsoil system for about 20 years with the Perkins engine, and the Australian Jackmaster system for three years with my newer small Yanmars. Both would work well if you had easy access to commercial filters and synthetic oil. The Amsoil system uses a large filter housing with an expensive filter element that should be changed about every 500 hours, according to their engineers. Amsoil recommends use of their synthetic diesel oil and periodic laboratory oil analysis. Then you do a full oil change of the oil when the oil analysis indicates it is needed.

Unusual filter materials

With a new boat, I have switched to the Jackmaster system because I think it has several advantages for overseas cruisers. The Jackmaster filter housing will require inexpensive but very tightly wound toilet paper rolls, which have been proven to make fine filter media. Contrary to what you might think, paper does not break down in oil as it would in water. It actually becomes stronger. The toilet paper rolls remove and store contaminants down to half a micron in size and also remove all water in the oil. It is recommended that you change the toilet paper rolls every 100 hours to keep contaminants out of the oil all the time. When you change the roll/filter, topping up the system with new oil to replace what was removed in the old element (a bit more than half a liter), sufficient new additives are added — especially with smaller-capacity engines — without a complete oil change. A very knowledgeable friend, who researched all the systems a few years ago, has been using the Jackmaster system for many years now. He recommends it as the best system for cruisers.

Installing any bypass oil filtration system takes some engine knowledge. The intake to the filter housing needs to come from a pressurized oil tap on the engine. Installing a “T” at the oil sensor fitting provides a good spot to attach a quarter-inch oil hose to the bottom of the filter housing. I used that on the Perkins, but on the Yanmars I found a small oil plug on the engine that provided a good option.

Then, the filtered oil needs a return to the engine sump. On the Perkins engine, there was a plug near the top of the oil sump that provided a good return spot. On the small Yanmars, I use a small hose fitting that fits snugly into the oil dipstick hole and is easily removable when I want to check the oil level. Of course this requires me always remembering to put it back when I’m done, a lesson I have learned by experience (several times!). Another option is to drill and place a hose fitting in the oil fill cap.

In summary, bypass oil filtration, while there is some upfront cost, provides significantly better oil filtration and saves considerable time, money and oil usage compared to standard oil changes. Using synthetic oil is even better for the engine. Not having to carry gallons of extra oil on board or dispose of it after use is an added benefit for cruisers. The technology is not new, has been well documented and is used by most large diesel fleets around the world. This even makes sense to my oceanographer brain. And Sherry approves because she has more room for wine!

Dave McCampbell is a retired U.S. Naval diving and salvage officer with more than 40 years cruising and eight sailboats’ worth of maintenance experience. He and his wife, Sherry, recently cruised the Philippines and Southeast Asia and earlier spent eight years crossing the Pacific. They sold Soggy Paws, their CSY 44 monohull of 19 years, and moved to the “enlightened side” in 2015, purchasing a St. Francis 44 catamaran, also named Soggy Paws.