We had just arrived in the Galápagos Islands and were wending our way through all the cruising boats looking for a spot to drop the hook. I noticed a fishing float that appeared to be moving our way. Our prop had picked up a lost fishing line, and within seconds, the float disappeared under our boat. Fortunately, it didn’t stall the engine as it was only a minute or two before we found a place to drop the anchor and were able to safely cut the engine. As soon as we were settled in, I dove on the prop. We had several hundred feet of monofilament tightly wrapped and melted into place around the prop and shaft.

Luckily, there was a local dive shop close by and after renting a tank, I began sawing and cutting the line. One tank wasn’t nearly enough. It took four tanks, three dinghy rides ashore, and the better part of a day to remove the line. Had the dive tanks not been available, it would probably have taken days to clear the prop by free diving.

This adventure emphasized that it would be nice to have some sort of underwater breathing apparatus on board to handle emergencies. It would also make routine bottom and prop cleaning easier.

|

|

David Lynn |

|

A quick disconnect fitting. |

A few solutions came to mind. I could buy three or four dive tanks and keep at least a couple filled and ready. This would necessitate transporting dive tanks to the local dive shop in whatever port we were in, sometimes a challenge in more remote areas. I could buy a dive compressor, which would allow me to refill dive tanks aboard. Dive tank compressors were expensive, noisy and large, and required either a lot of electrical power or to be engine-driven. A third solution was to buy a hookah system with compressor. Unfortunately, commercial hookah systems are also expensive and large.

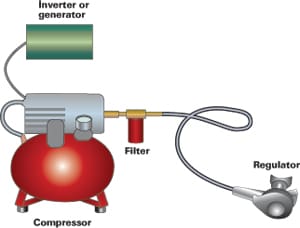

After doing a bit of research, however, I didn’t see why I couldn’t build my own hookah system. Essentially, I would need an air compressor, filter, 50 feet or so of hose, a dive regulator, and the necessary connections. While most of the commercial systems I saw were designed to provide enough air for two divers diving to a depth of 50 feet, my needs were much simpler. I would be using it alone, never in tandem. I would be working at a maximum depth of eight feet or so, while the usual working depth would typically be more like three to four feet. If anything went wrong, I could be at the surface with one kick, and I certainly wouldn’t be deep enough to need decompression stops on my way up. After a bit of trial and error, I was able to build one that has been working quite well for several years now.

The layout of the hookah is shown in accompanying schematic. The first step was to find and modify the regulator. I wasn’t sure that a standard dive regulator would work at the lower pressures of a hookah system. In a standard diving arrangement, the first stage regulator reduces the tank pressure to 150 psi, and the second stage regulator and demand valve is designed to work at this pressure. Most inexpensive compressors will provide less than 100 psi. There are low-pressure and variable regulators available at considerably more money, but I thought I could modify a standard regulator to work. I found several online for less than $100, but decided to buy a used one from a local dive shop for $35.

The heart of the system was the compressor. Obviously, the first requirement was that it must provide adequate air pressure, flow and volume. I wanted an electrically-driven, oil-less type, so there was no chance of breathing carbon monoxide or petroleum vapors. Also, it had to be small enough to stow aboard, and the power requirements should be low enough that I could power it from either my inverter or my portable 2-kW gasoline generator.

I wasn’t sure how to calculate how much air pressure, flow and volume was needed, so I cobbled the basic components together and did some trial and error with a few compressors I was able to borrow. What I found was that, at a minimum, I needed a compressor that would deliver at least two standard cubic feet per minute (SCFM) at 90 psi. As it turns out, this size compressor was commonly used for paint spraying, nail guns, etc., and was not only easy to find, but quite inexpensive as well. I also discovered that my newly purchased regulator worked just fine with this lower pressure and would not need modification. I purchased a compressor with an output of 2.6 SCFM at 90 psi and a six-gallon air tank. The tank allows the compressor to cycle on and off every few minutes rather than running continuously.

|

|

David Lynn |

|

A filter for removing dirt particles. |

I connected a standard pneumatic air filter and water trap to the compressor with quick disconnect fittings to prevent rust or dirt particles from being inhaled. It also filters out some of the moisture in the air, but I suspect this is less important. After all, I am breathing underwater with it and probably inhaling considerably more water vapor than the filter strips out.

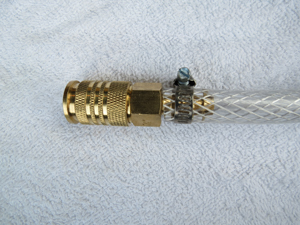

The next step was selecting the hose. I looked at everything from inexpensive rubber pneumatic hose to mil-spec diving hose at several dollars a foot. I think if I was using this hose on a daily basis and diving to greater depths, I would be more inclined towards better hose, but for my application, a reinforced food-grade hose seemed the right compromise. I found 3/8-inch reinforced, food-grade air hose rated for 250 psi online for $0.40 per foot and purchased 50 feet. I used a brass barbed fitting adapter on each end and attached a brass pneumatic quick-disconnect fitting to the adapters.

To make the regulator easier to connect and disconnect to the hose, I cut off the end of the regulator hose and replaced it with a brass barbed fitting adapter and male pneumatic quick-disconnect fitting.

To use the system, I bring the portable gas generator and compressor on deck and make all the connections. For obvious reasons, I make sure the generator is downwind of the compressor. Then I flake out the hose into the water on the side I will be working. I use a Velcro strip to attach the hose to my upper arm, so that if I have problems or the hose becomes tangled, I can quickly detach myself by pulling the Velcro strip.

The next step is to start the generator and check the system for airflow and leaks. Then I climb into the water and get to work. Marcie keeps an eye on things topside to make sure my bubbles keep coming up and no problems arise. Before stowing everything, I give all the brass fittings a rinse in fresh water.

I have used the hookah system several times to clean the bottom, once to clear fishing line from the prop and twice to replace hull and prop anodes. It has performed flawlessly every time. One time, I loaded my portable gas generator and hookah system into the dinghy and spent six hours searching for a friend’s lost prop in a shallow anchorage off Opua, New Zealand. The depths ranged from six to eight feet, ideal for a hookah system. (Unfortunately the search was unsuccessful — it’s still buried in the mud there somewhere.)

Safety issues

Before you build your own hookah system, there are a few warnings:

1. I’ve never used the system at a depth greater than about 15 feet. I do not know if the described compressor/regulator combination will provide adequate air, or indeed work at all, at greater depths.

2. Even if the compressor and regulator do work in deeper water, I would definitely recommend having a backup system if using the home-brewed hookah system at any depths greater than you would feel comfortable free diving. If a fitting comes loose, the generator quits, the compressor stalls, or any number of other possible malfunctions occur, you will have to be able to swim back to the surface. As any diver knows, your ascent should be slow, no faster than 60 feet per minute, which could be difficult if a hose came loose and you have no backup system.

3. If you are working at depths greater than 30 to 40 feet for any length of time, you may need a decompression stop before surfacing. This would be impossible if there was a malfunction and you were dependent solely on the hookah system. The ideal backup system would be a separate dive tank and regulator.

4. Finally, there is no legal requirement to be a certified diver before using a hookah system, but the training received during a certification class is invaluable in keeping yourself safe when diving, whether using scuba gear or a homemade hookah.

———-

David Lynn and his wife Marcie live aboard their 45-foot 1986 Liberty cutter Nine of Cups.