Batteries are the heart of your boat’s electrical system. If improperly installed, however, they can also be a very dangerous part of your electrical system. Batteries contain a large amount of energy, along with some unpleasant chemicals that can leak, and every now and then a battery may explode. Given this, safe battery installations are important.

As a surveyor, I get to see a lot of battery setups and some are better than others. Based on what I have seen, many owners do not fully understand what makes for a safe installation. Properly installed batteries are not only safer but will last longer, saving money in the long run. Poorly installed batteries, on the other hand, can become a hazard and may not provide the dependable power needed. Many owners and even some boatbuilders do a poor job of properly installing batteries so that they will provide safe and dependable power.

Fortunately, there is a set of guidelines that can help avoid any problems. The American Boat and Yacht Council (ABYC) has developed a set of common sense recommendations on how to install batteries. I know many get defensive when they hear talk about meeting “rules,” but I think most will agree these rules make sense. Before you lose interest thinking I am going to recite a bunch of regulations, fear not; I am just going to focus on the “how” and “why” of a good battery installation. In the end, your installation will be up to “code” if you follow these recommendations.

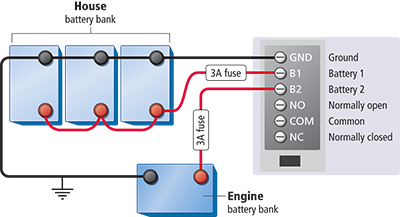

|

|

A classic battery setup is a house bank for general needs and a battery for engine starting. These are connected to a monitoring unit, such as the Balmar Smartgauge. |

Most marine batteries are the lead-acid wet-cell type commonly associated with car batteries. They are heavy and filled with an acid solution. Most are vented on the top to allow hydrogen and oxygen gases to escape during charging. Hydrogen, of course, is a highly explosive gas — the same stuff that brought down the Hindenburg zeppelin. The combination of hydrogen and oxygen is what causes batteries to explode when things go wrong. Many boaters will also use gel-cell or AGM batteries, and although many of these are sealed, they can and do release gases when overcharged and have also been known to explode.

Respect battery power

Regardless of the battery type, the installations should be the same. Batteries work by a chemical reaction and these chemicals can be a hazard if spilled. Batteries also contain a large amount of electrical energy. The bigger the battery or battery bank, the greater the energy potential. Anyone who has ever accidently shorted a battery knows only too well the power contained in a fully charged 12-volt battery. It can easily melt metal as well as start fires. It goes without saying that keeping this energy and the acidic chemicals properly under control is important. Add to that the weight of the batteries and the movement of the boat, and it becomes clear that solid installation is important.

Any battery setup needs to meet a few basic requirements to not only be safe but to help protect and secure the batteries from damage. It also needs to be kept in mind that no matter what type of battery being used, the requirements will be the same. Some will argue that modern sealed batteries do not leak and therefore do not need boxes; the truth is all batteries can fail, sometimes catastrophically, and it is important to protect the boat from damage. It also needs to be kept in mind that replacement batteries may not be a sealed type.

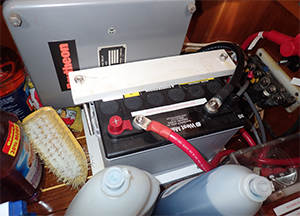

|

|

Well secured but no box or cover to protect the terminals. |

The first consideration is where to install the batteries. This is often already decided by the boat’s builder, but when adding batteries or installing larger batteries, some changes may need to be made. Many builders install batteries almost as if they were an afterthought, so it might pay to review the builder’s installation to see if improvements can be made.

When picking a location for the batteries, there are a few things to keep in mind. As batteries are heavy, the weight should be down low in the boat. You also want easy access for maintenance and service. The location should be well vented to eliminate explosive gases and also to help cool the batteries. Some space should be provided between the batteries if possible to allow for cooling as well. Batteries are less efficient and their life will be shorter if they are constantly hot. You also do not want anything directly over the batteries — this is particularly true with battery chargers, inverters and other electronic equipment. This is not only to prevent explosion hazards but to protect the equipment as well. Hydrogen and oxygen gases are corrosive and will shorten the life of electrical equipment mounted above or too close to the batteries. The most common location for batteries is in the engine compartment. While this may seem to be in conflict with the heat requirement, it will not be a real problem if the batteries have good air flow.

All battery installations will require some ventilation. This does not necessarily need to be a forced air system using a blower; natural ventilation can suffice if the airflow is reasonable, as in an engine compartment. For batteries stuck under a bunk or in any area without airflow, it is wise to add some ventilation. You want to do this first to remove flammable and corrosive gases and, secondly, to help cool the batteries — particularly during charging. I have seen some installations using a small computer fan on a voltage-sensing switch. When the voltage increases due to charging, the fan comes on. During charging is also when the most heat and gas will be released, so this is a good way to go.

Steve Higgins, technical support manager at Rolls Battery Engineering in Springhill, Nova Scotia, makes the point that ventilation is a big consideration for siting batteries. “All batteries gas — AGM’s do gas in the absorb stage — and when the temperature of the battery gets too high these will vent gas,” Higgins said. “Flooded batteries need active ventilation, while AGM batteries you can usually get away with passive ventilation. I personally like to see active ventilation on AGM banks that are installed in engine rooms, or small rooms in general.”

Once a suitable location has been worked out, the way the batteries are mounted to the boat needs to be considered. A box or tray, preferably with a lid, should be used. Should a battery fail catastrophically, a box and lid will help contain the carnage. They will also help protect the batteries from damage from an outside source such as stowed equipment.

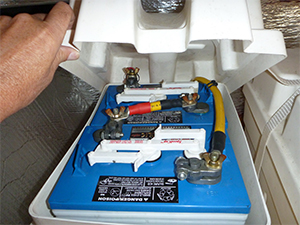

|

|

This battery has its own box and lid. |

It is acceptable to use a single box for more than one battery. If you’re doing this, have a bit of separation between the batteries to reduce heat buildup when charging. I often get the argument that a box or tray is not needed with sealed batteries. ABYC uses the logic that at some point the sealed battery may be replaced with a wet cell, which is a valid argument. Sealed batteries can and do explode, although it is not as common. These are all good reasons to have the batteries in a box.

Well secured

It is also important to make sure the battery is well secured to the boat. ABYC recommends that the battery not move more than one inch in any direction with a force equal to the weight of the battery. This is common sense, and even more important for boats that may venture offshore. Most battery tie-down straps found in local marine supply stores do not come close to being strong enough to secure the average battery, and even some of the better tie-down straps only use small screws to secure the strap to the boat. “With AGM/gel batteries, make sure your straps don’t cover up the valves on the top of the battery,” Higgins said. “Doing so will prevent the valves from opening due to over-temperature and will accelerate failure in warm temperatures.”

A better system is to use ratchet-type cargo straps connected to eye bolts, and crossbars with threaded rods bolted to the boat also work well. Try to imagine that you turned the boat upside down and shook it. Would the battery remain in place? This may seem extreme, but it is a plausible worst-case scenario and it is not that hard to properly secure the batteries for even this extreme case. I have heard of batteries coming loose in less severe conditions and the results are never good. Keep in mind that it is in severe conditions that the batteries will likely be needed most.

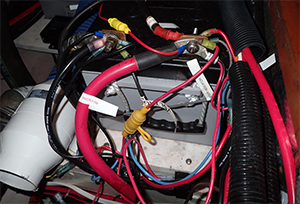

|

|

This battery has too many connections and could use a sub panel, a box and terminal protection. |

Batteries contain a lot of electrical energy — hundreds of amps in most installations. This energy is always ready and willing to be released. Because of this, ABYC recommends covering the positive terminals on batteries to prevent accidental shorting. If you have ever accidently shorted the battery terminals, you will understand the reasoning on this. A battery in a box with a lid will meet this requirement, but if that is not possible there are several companies that make rubber boots to cover the positive terminals. In a pinch, split hoses will work; the idea is to protect the positive post and connections from contact with anything that could short it out.

The batteries should also be located where they will be accessible for inspection and service. This is particularly true for wet-cell batteries, but it is also important for sealed batteries. With wet-cell batteries, it is of course important to be able to check the fluid level, but all batteries should be inspected for physical problems as well. It is important to check all the wire connections as well as the general condition. Swelling cases and/or cracks can be a sign of problems. It is also a good idea to check the battery temperature with an infrared thermometer, as a hot battery is possibly a sign of a failing battery.

Dependable connections

With the batteries properly mounted, the last part of the installation is connecting the wires. This is another area where problems and poor installation occur. It is common to see several wires all piled onto a single stud and, in some cases, some creative engineering to increase the number of wires that can fit on the stud. ABYC recommendations only allow for four connections to a single stud — this makes sense, as the more conductors on a stud the more likely you will end up with poor connections. When it comes to making connections to the battery post, less is better. The best arrangement is to have only one cable connected to each post and securely fastened with a clamp. Wing nuts should not be used as they are harder to fully tighten. The connection should be checked regularly for tightness and any corrosion.

|

|

An example of terminal corrosion due to poor maintenance. |

The single cables from the battery should go directly to a battery switch on the positive side and a buss bar on the negative side. It is best to keep the battery switch as close to the battery as is practical. This consideration needs to be balanced with the need to access the switch in an emergency. Several companies — such as Blue Sea Systems — now make remote battery switches, making it even easier to have the switch close to the battery.

After the battery switch should be a sub panel with breakers or fuses for all those wires that would have been connected directly to the battery. Any starter cables can go directly from the switch to the starter without a fuse or breaker. Many boatbuilders are now installing sub panels like this near the batteries. They will install breakers for things like automatic bilge pumps, alarms, monitors, stereo memories and anything that should not be turned off by accident. This setup works well for safety and reducing clutter at the battery. All ground wires should go to a buss bar located at or near the sub panel.

A good battery installation is not hard to achieve, it just takes a bit of effort and some common sense. A proper installation will not only help keep your boat safe but will also increase the life of your batteries. It will also help protect the boat from damage due to acids and corrosive gases. It may pay to review your installation and try to incorporate as much of these “rules” as you can. There are several great products from battery boxes to buss bars that will help make a proper installation easier. Remember, a poorly installed battery is a hazard to both the crew and the vessel, and it will likely also shorten the life of the battery.

Wayne Canning is an author and photographer and a licensed surveyor. He lives aboard his Irwin 40 Vayu in Florida. Visit www.4ABetterBoat.com or www.projectboat.info.