Editor’s note: This is the second of a two-part series on making sure you have the spares you need for your power voyaging boat.

I like to advise my clients that it is a smart tactic when you purchase a spare part to immediately put it in service. Take out the good working part and make it the spare. This way you confirm that your new part fits correctly and you know the part you replaced will work – it’s already done its duty and is an ideal reserve. It’s a real disappointment if you wait to make a change only to find out that the spare part you have on hand is the wrong size or model.

Another approach to help you figure out your spare parts strategy is to envision where are you most vulnerable. It is wise to think about the key things that, if broken, would ruin your day or cut your trip short. All breakdowns are an inconvenience and some may even jeopardize your safety.

Here are two common problems you can create solutions for with this method:

|

|

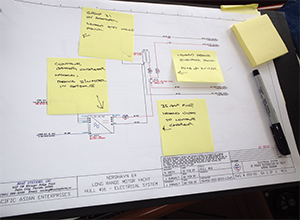

One approach is to diagram the locations of needed spares as in this case using Post-It notes on a Nordhavn 64’s electrical system. |

Toilet malfunction? Not fun at all, and better if you have two heads, but a good working head is a luxury that many of us simply can’t go without. The same can be said for making sure you can properly empty your holding tank.

Freshwater pump shut down? Water tanks are full, but your accumulator pressure tank is not holding air or your pump breaks down. How will you get water to your faucets? A backup freshwater pump, preferably pre-plumbed and ready to go, is high on my list of recommendations.

Tales of woe

Reading cruising blogs will reveal tales of woe and introduce you to a great number of situations boaters face and how they resolved them. Your boat is always sending signals (telltales like drips, stains, etc.); your job is to identify these clues by looking, listening and smelling. You can’t ignore a problem and expect it to go away.

When the dust settles and you are back in business, rehash what happened and see what you can learn so that next time you can more quickly make the correction. What changed? What caused it to quit working? If a fault occurred due to chafing, add some padding. Look at repairs with an eye for preventative maintenance in order to improve longevity of parts and systems. This is also the time to update your maintenance log to record the details of what occurred and document your repair, including part numbers and date so you have a record of gear failures.

|

|

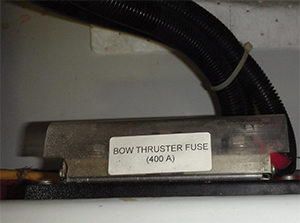

An example of labeling fuses with their function and their amp rating. |

Inventories of major “just-in-case” spare parts are difficult to accumulate without an unlimited budget. You don’t have the space to store everything you would need to completely rebuild your boat, so you need to be practical. “Essential” spare parts are unlimited — where do you draw the line? It would be a huge expense if you insisted on stocking steering rams, engine starters, alternators, etc. The convenience of having the parts on board to immediately initiate a repair needs to be weighed against the parts’ cost of purchase, the amount of space utilized and the possible deterioration of this extra gear languishing in a moist boating environment. This is a personal decision that has no right or wrong answer. Purchasing replacement parts depends upon what you think is best for you and the type of cruising you are doing.

For example, you probably won’t have a spare inverter waiting in a box, but if you have a generator then installing an inverter bypass might be a nice upgrade before you sail off the grid. I’ve seen people take a spare windlass and not bother greasing the good working one they have, which becomes a bit of a self-fulfilling prophecy. If you have ever lost a windlass, you know it is no fun trying to horse up an anchor — another situation where you should devise a plan B solution.

DIY approach

There are really two strategies for stocking up on spares. The do-it-yourself boaters prefer to have everything on board and stockpile equipment. These are the owners with built-in vises, power tools and lots of engineering experience. Wisely, they catalog their inventory and often store parts after wrapping them in Ziploc bags or with airtight, vacuum “seal-a-meal” plastic for preservation. They seal them in the packaging they arrive in so they are impervious and won’t get soggy. Some trawler owners use those silica gel moisture-wicking packets to ensure packaged goods stay dry. Many of these owners use snug-fit clear plastic bins that are ideal for spare parts storage. They also document where things are stowed and keep a detailed inventory account. I’ve sold their boats for them when they are done cruising and watched the new owner marvel at over $10,000 worth of spare parts inventory and gear that have never been used. It was there if they needed it, and that is what was important to them.

|

|

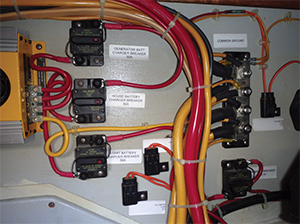

A selection of spare fuses. |

HIRE boaters

The other approach is the HIRE boater; they (and I’m one of them) know enough to poke around, troubleshoot and complete a makeshift repair, but would not feel comfortable changing out engine injectors or rebuilding an alternator. For those of us who can change filters but aren’t even sure what spare parts to buy even if we could afford them, our best strategy is to know what parts we need and know where to purchase them when needed. As far as high-end, big-ticket components, I think you are better off not trying to anticipate every possible malady and instead resign yourself to the fact that when you need to make a fix you will have to bite the bullet and pay exorbitant shipping costs and delay your departure. With DHL and FedEx, it is reasonable to expect that a part can arrive by air within five days to a week. You may be stuck in paradise and miss the next weather window, but the air freight expense over several years of cruising will likely total a lot less overall cost than the gold mine of spare parts the DIY has left over when they sell their boat.

Sometimes all you can do is cobble together an on-the-fly repair that will allow you to arrive safely back in port. One of the best multi-use products is rescue tape. It can be used to stem leaks on most hoses and is a very strong, versatile and waterproof sealer. Spare lengths of hoses and hose clamps should also be in your inventory. Keep duct tape and cable ties handy.

Most repairs are the result of normal wear and tear of active parts. However, not everything wears out due to use; some items expire naturally over time. I am always surprised that pencil zincs (sacrificial anodes used on raw water-cooled engines and generators) are often overlooked. Many owners don’t even know they exist and thus don’t know they need to change them out. Consult your service manual, find where they are and make them easy to remember by marking the ends with a red permanent ink pen. Cataloging your maintenance service chores and referring to your paperwork will help ensure you don’t forget. I like to put a date label on replacement filters so that I know both when I changed them and at what hour the next change is due.

|

|

Replacing failed parts is easier if various elements are labeled, like these parts of a power voyager’s electrical system. |

Another good practice is to develop an individual data sheet for each major component. Many boaters record all of their service work in one all-encompassing maintenance log. This is a much better approach than simply saying you did the changes when you were supposed to but not recording your work. My recommendation is to make a separate Excel spreadsheet for each major piece of equipment — engines, generator, stabilizers, thrusters, windlass, crane, etc. — and keep them all in one binder. Each data sheet should have the machinery component, model number, manufacturer or dealer contact, common spare parts by number and a running record of when you completed a service update. While this is a chore to set up, it is a habit that, if followed, will increase your boat’s desirability for the next owner.

It’s hard to predict what you are going to need — experience is the best teacher — but, in this case, planning does not breed misery. You can’t go too wrong if you acquire items that are going to help ensure your safety underway. There is a necessity to be somewhat self-sufficient if you want the freedom and independence that long-range cruising affords. You rarely have time to spare when the stuff hits the fan, so think things through ahead of time and implement a spare parts strategy that prepares you for the inevitable.

Jeff Merrill, CPYB, is the president of Jeff Merrill Yacht Sales, Inc.- www.JMYS.com. He is a veteran yacht broker who provides individual attention and worldwide professional representation to buyers and sellers of premium brand, oceangoing trawlers. Merrill is active in the cruising community as a public speaker and writer and enjoys spending time at sea with clients. Jeff has written several “Dialing-In” your trawler articles for Ocean Navigator’s Power Voyaging column and is constantly looking for new ideas to improve and simplify the trawler lifestyle. If you have a suggestion or want to get in touch, please e-mail Merrill at: Jeff.Merrill@JMYS.com.