Vendee Globe yacht designers literally spend years between each quadrennial event refining their designs to create a hull, with its appendages, that is both durable and lightweight. This gives their skippers the best chance of completing the 24,449.6-nm course in one piece. Roughly 30 to 50 percent of competitors are likely to complete the race, though this year’s odds may have diminished even more, given that seven competitors are using semi-foiling hulls.

A great deal of research has been done since foiling became popular with the America’s Cup, and it has migrated directly into monohull ocean racing. Designers are now on what is called the second generation of foil design, making them faster, more efficient and even safer than the first generation. But, adding foils to an existing hull or incorporating them into a new design is an expensive proposition. There is a great deal of development necessary to optimize the design so that the hull and foils work in conjunction with each other and provide the right amount of lift while not hampering performance and ideally reducing pitch and lowering wetted surface.

The Dali mustache

Today’s latest foil design is referred to as the “Dali mustache” because of its likeness to the surrealist’s iconic facial hair. These foils work particularly well when reaching in heavy air but add significant drag in light air and provide little horizontal lift when sailing upwind. Their chief drawback is that they extend out of the sides of the yacht and thus are much more exposed than daggerboards and susceptible to hitting unidentified floating objects (UFOs).

Yacht designer Merf Owen and his business partner, Allen Clarke, have been creating custom Open 60s since the 2000/2001 Vendee Globe. Kingfisher was their first, followed by Ecover 2, Temenos, Ecover 3/Aviva and Acciona, to name a few. This Vendee, Owen Clarke Design has three of their older non-foiling yachts in the race, but has done extensive research on foiling for potential clients. And, despite their remarkably busy schedules, they’ve provided insight into the specifications and design parameters associated with foiling technology.

|

|

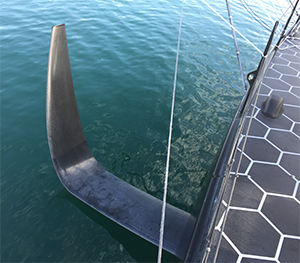

The foil on No Way Back is reminiscent of a gull’s wing. |

|

Brian Harris |

Speaking specifically to the physical demands placed on foils and subsequently on the foil boxes that hold them in place, Owen said, “A challenge created by physics is that, for the same area, the loads on a foil increase by the square of the boat speed. The load when the boat is doing 30 knots is nine times the load of when the boat is doing 10 knots and the foil must be engineered accordingly. Horizontal foils also, by their very definition, must support the entire mass of an Open 60, which — in Vendee mode with water ballast — will be over 10 tons.” The additional foil structure and the weight that it carries is then supported by the foil box, which holds the foil in place and stops water from entering the hull of the boat. But it is a significant carbon-engineered structure that adds more weight. “On the plus side,” said Owen, “the weight is lower down, with a lower vertical center of gravity than their vertical (daggerboard) counterparts. Thus, the additional strength/weight required to operate in the harsh conditions of Vendee/transoceanic sailing isn’t ‘wasted.’ However, because the horizontal foils extend outboard of the yacht, they are anecdotally more susceptible to impacts with surface debris, ice, etc. One other consequence of their geometry is that they don’t tend to protect the leeward rudder from impact in the same way that a vertical daggerboard does.” Morgan Lagravière’s Safran retired from the Vendee Globe on Nov. 24 under these very circumstances.

Compared to the foils, more traditional daggerboards present their own set of benefits and drawbacks.

“With conventional daggerboard systems,” said Owen, “the upwind load is 12,000 Newtons and, when reaching, up to double that. But by this time you’re ‘reefing the board,’ raising it so that you reduce bending moment and drag. You only need so much side force, as you’re not trying to lift the boat. Since you only need to produce side load with conventional forces, one can engineer the boards relatively light. … The skipper is required to monitor the speed and usage of his boards. We keep them light because obviously when they’re in the air, not being used (at least one always is), the center of gravity of these 3.7-meter boards is above deck level. Our boards are designed to an ultimate load of 49,033 Newtons, so it’s possible to break them if you leave them down when you’re doing 20 knots for instance. But our boards only weigh 42 kilograms.”

Engineering costs

As Owen pointed out, related costs are not that different in terms of the materials needed. “A 60 needs foils and boxes anyway, so the costs for the actual foils that are bandied about don’t necessarily reflect the actual ‘increase’ in cost of construction,” said Owen. “This, we think, can add up to less than 100,000 euros.” But, the real costs are incurred in the man hours dedicated to using computer modeling, velocity prediction programs, computational fluid dynamics, development engineering design and finite element analysis. “These numbers quickly outstrip build costs the more candidate designs one develops,” he said. “We allocated a budget close to 200,000 euros for this part of our new design, but one could easily double that and no doubt some teams have over a two-year period.”

|

|

Hugo Boss’ black foil suggests the fins of an orca. |

|

Brian Harris |

Time spent developing foils can also quickly slow a program’s development. According to Owen, many man hours can be devoted to developing the foils to the point where they’re most effective in their speed range, as well as removing or mitigating the problems reported in the first year such as control issues and accidental gybes. “Whenever a boat is out of commission in the yard or in refit, it’s lost time that could be spent on the water developing other aspects of the boat,” he said.

Beyond the delicate balance between program costs, foiling and non-foiling hulls, there is the added liability that foils add, and a skipper’s ability to manage them effectively and ensure that they can finish the race in one piece. “Personally, I think it’s doubtful that we won’t be seeing damage from most of the foilers,” said Allen Clarke. “You will note that boats like Alex Thomson’s Hugo Boss are very optimized and his foils and boats are a bit more extreme than others. Thomson must reduce his foil area earlier (since) his boat reaches its optimum conditions sooner. The French teams all have a different take on the foil configuration’s size/position, but none are as extreme as Thomson’s. It’s all down to the sailing course ultimately — boat management, knowing when to ease off the fast pedal. The biggest problem outside of all this is going to be unidentified floating objects and this is likely to be the demise of many a foil.”

Structural issues

Given that the average speed of the foilers is often so much higher than the non-foilers, it is important to consider the structural issues related to foils and what happens when they hit UFOs. “The foils do raise structural issues,” said Clarke. “But really these items are designed to be fused (there is a break point). Designers have been doing this for years on rudders, daggerboards, etc. Again, the crash box for the foil casing inside the boat needs to be engineered to just the right degree of weight versus strength. It would be a shame if all the foilers had snapped their foils and still tried to finish the race, or a boat couldn’t complete the course because of damage to the boat due to foil breakage. It shouldn’t happen and I think it unlikely. The loss of the foil is a big disadvantage though.”

As with all technology found in the latest yachts, be they America’s Cup cats or Open 60s, the question remains: Will the equipment and expertise trickle down in one way or another to less expensive and technical yachts? Walking around the docks in Les Sables-d’Olonne prior to the Vendee’s start, you certainly get a sense of that excitement. Bruce Schwab, the first American to finish the Vendee — and one of the many who descended upon the French port city to work on Hugo Boss and other participants’ energy systems — is optimistic. “I was able to go for a sail with Alex Thomson when the boat was in Newport, R.I.,” he said. “I was a kid in a candy store, absorbing every detail that I could. The new boats are spectacular, a whole new dimension of speed. They are faster than multihulls were a few years ago. No doubt the level of technology to do what they do is very expensive. However, like all tech that develops for the Vendee Globe, it will trickle down, and that is very exciting for sailing in general.”

|

|

The deck spreaders and hull foils of Edmond de Rothschild show how different one of these racers are from the average voyaging boat. |

|

Brian Harris |

Foil-assisted voyagers

But just how far down the sailing food chain they will go is questionable. Certainly there is opportunity to move foiling more into ocean racing, but it may be difficult to break into the broader cruising market than some think. “You don’t want to over-build a foil, you want it to break if it hits something,” said Clarke, who doesn’t believe foils will be popular for bluewater cruising. “They take up a lot of room inside the boat, they have a narrow optimum performance band, they are expensive and liable to break, and the noise is pretty awful. If, however, your cruising was more camping on water, then it’s possible we might see some foil-assisted craft. I think the Gunboat G4 was probably the best example of how this might be. However, cruising habits will need to change and people will need to learn to be modest in the fit-out standards of their boats, hence why I think there will need to be a change in the way people cruise if foils, in the sense of what we are seeing in the America’s Cup and the Vendee Globe, were to become commonplace.”

Another option might be foiling rudders. While interviewing Pieter Heerema of No Way Back, his shore team was positively excited about just such a prospect. “But again,” said Clarke, “they are going to be prone to damage and any advantages could easily be wiped out accordingly. I think the initial cost/performance/reliability equation will always err on the side of reliability for a serious cruiser.”

Ross Tibbits, a San Francisco native, is an avid racer. He writes about sailors, designers, tech and the environment.