How much do you know about your trawler’s manual bilge pump? Better than a bucket brigade, a good manual bilge pump can send a lot of water back to the sea, especially when it is powered by adrenaline. Dewatering your vessel is a critical safety procedure that every trawler owner must understand. Sadly, it is one that often goes underappreciated — that is, until you need it.

Your trawler’s hull shape will determine where you have low spots, and since water follows the path of least resistance and gravity guides it to seek low ground, it is imperative to know how to discharge any liquids that you collect.

Monitoring the level of fluids in your bilge cavities needs to be part of your regular routine inspections, whether you are underway or at rest. Bilges are designed to accumulate excess water, and pumps that use suction and/or pressure are installed to remove it.

|

|

The classic hand-held pump comes in handy when bailing out a dinghy. |

You should know where bilge water will collect aboard your vessel, and inspect under floor hatches or in machinery space sumps to keep an eye on what is happening. If water appears where it wasn’t before, then something has changed and not only do you need to activate your bilge pump to clear it out, but you will also need to determine the source and stem the flow.

It is unlikely but still possible that at some point you will lose electricity aboard; in this situation, you’ll need to go back to basics and discharge water the old-fashioned way. Here are some thoughts to consider.

Bailing out tenders

As a dinghy sailboat racer, I know that the extra weight of water that splashes aboard or pours in over the gunwale when I heel over too far will slow me down. I carry a bailer — a plastic bleach bottle or equivalent with the bottom cut off to create a scoop opening. With the cap left on, I use the handle for a grip and can quickly shovel over unwanted water. My bailer is tied with a bowline on the handle and then secured to my boat via a 6-foot thin line so that I can’t lose the bailer if I am too aggressive with a scoop and let go by mistake, or if I capsize and all of my loose items start floating away. I also carry a sponge to mop up the small amount of water remaining that the bailer can’t reach so I don’t have to sit in a puddle.

|

|

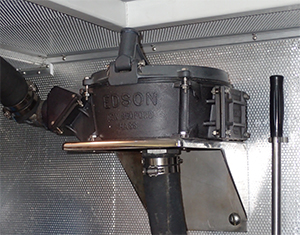

A high-capacity Edson diaphragm pump with its handle stored nearby. |

Shortly after the invention of the still very useful bucket (and cut-off bleach bottles), suction tubes were designed to lift water out of low spots and discharge it overboard. Products like the Beckson “Thirsty-Mate” hand pump are very practical for emptying water out of small craft and shallow areas aboard your trawler. They are corrosion-free, lightweight, inexpensive and efficient. Many trawler owners I know keep one of these simple lift pumps in their tenders for removing rain and splash water.

Manual bilge pumps

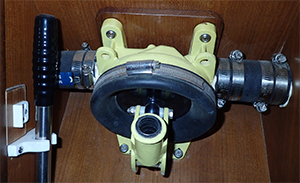

Manual bilge pumps often are equipped with larger-diameter hoses for more volume. A high-capacity manual bilge pump is essential safety gear to have when you travel offshore. These typically have a large rubber diaphragm and are operated with a lever or handle.

Diaphragm manual bilge pumps use a handle or lever to open and close a rubber membrane, sucking water in from a hose with one end deep in the bilge and ejecting this bilge water overboard. Edson makes an evergreen product: Their 638 models are better known as the “Gallon-Per-Stroke” pumps and can evacuate 30 gallons per minute.

The membrane is most commonly made out of rubber because of its elasticity and resilience, but rubber can be damaged by petroleum products like diesel and oil. So, if you do pump out fossil products (and are alert to environmentally conscientious removal), your rubber membrane can deteriorate.

Be sure to stow the pump handle nearby so it is not hard to locate when you need to start stroking.

Learn where on your boat your bilge receives liquids and if your bilges are connected via limber holes. Some trawler chain lockers drain into the bilge, as do many air conditioning compressor condensate pans. If you have a leak of any type of liquid — fresh water, black water, diesel or oil — it can find a direct path into your bilge that serves as an all-purpose, non-discriminatory collection sump.

|

|

Another example of a manual pump, this time mounted in the pilothouse. |

Clean your bilges

After clearing your bilges, fill them with some soapy fresh water and cycle that through the pump and rubber drum skin to help dilute and protect your pump and parts. I know several owners who make cleaning out their bilges and operating their manual pumps a regular maintenance routine once or twice a year.

Pickup shoes that are at the bottom end of the bilge hose can clog with debris and should be inspected and cleaned so they are always ready and in good working order. If the shoe is not secured to the bilge floor, you should be able to use a wet vacuum (this requires electricity) to clear off particles by bending up the hose to expose the shoe bottom and sucking off the crud.

Manual bilge pumps require human power, and if there is a lot of water to ship overboard it can be a tiring process. It does not take long for a large amount of water to potentially overwhelm your manual system. If you are having difficulty keeping up, this is where power bilge pumps come into play — which will be discussed in a future article.

Jeff Merrill is president of Jeff Merrill Yacht Sales (JMYS.com). Get in touch at Jeff.Merrill@JMYS.com.