For as long as I have been experimenting with boat electrical systems, the limiting factor in DC systems design (and, indirectly, much AC systems design) has been the low charge acceptance rate of traditional lead-acid batteries (whether wet cell, gel cell or AGM). This is a particularly acute problem on cruising sailboats which, much of the time, have little need of an engine for propulsion purposes and therefore have extremely limited engine run hours available to power an alternator for battery charging. It is also a problem for any powerboat that spends a significant amount of time at anchor. Both classes of boat tend to have a more-or-less permanent energy deficit.

Here’s the problem. As a conventional battery comes to charge, its charge acceptance rate steadily declines until it is accepting little charging current, regardless of the power that is available. The only way to pump relatively large amounts of energy into a battery bank in a relatively short period of time is to operate the batteries in a well discharged state — say between 50 percent state of charge and 20 percent state of charge. However, if batteries are operated on a regular basis at these kinds of states of charge, they fail prematurely.

|

|

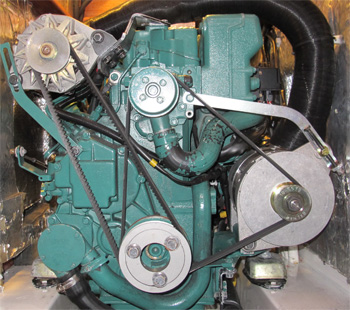

Calder found that high output alternators also produce substantial heat that can reduce output. Ducting away the hot air from the alternator helps it maintain a higher output. |

In order to avoid premature failure, the general rule of thumb is to prevent discharges below 50 percent state of charge, and to regularly charge to 80 percent state of charge, with periodic charges to 100 percent state of charge. Unfortunately, the charge acceptance rate at 50 percent state of charge is, at best, 40 percent of a wet cell battery’s rated capacity, declining to 15 percent at 80 percent state of charge, and just a dribble of amps above 90 percent state of charge. Gel cells have a moderately higher charge acceptance rate, and AGMs an even higher rate, but nevertheless all suffer from low charge acceptance rates at higher states of charge.

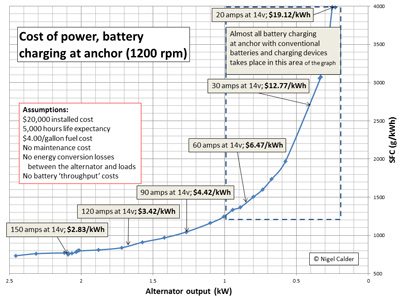

The dilemma is clear. You either run a fossil-fueled engine long hours lightly loaded to periodically fully recharge batteries or you kill the batteries in short order. In practice, cruising sailboat owners at anchor often end up running their main engine, or an auxiliary generator powering a battery charger, for two to three hours a day, while powerboat owners run a generator lightly loaded for even longer. In both cases, the average charge rate into battery banks is typically no more than 1 kW (approx. 80 amps at a nominal 12 volts) and generally less than this. With wet-cell batteries, up to 40 percent of this charging current is then lost during the battery recharge and discharge cycles, and with gel cells and AGMs up to 30 percent, so the effective net charge rate is only 600-700 watts. If you run through the numbers, including the amortization cost on the engine or generator, plus fuel and maintenance costs, it is not uncommon for boat owners to be paying $5 to $6 per kilowatt hour (kWh) for power generated on the boat (as opposed to 10 cents to 20 cents at home).

The solution

For the past couple of years we have had breakthrough battery technologies that more-or-less completely eliminate this problem. In the lead-acid world, we have thin plate pure lead (TPPL), most widely distributed by Northstar under the Energy1 brand label, and EnerSys under the Odyssey brand label, but also available in the telecoms world in the guise of SBS batteries. In the future, we may have lead-carbon batteries. Beyond this we have an ever-expanding range of lithium offerings.

What these technologies have in common is truly astonishing charge acceptance rates, the lithium even more so than the TPPL. Lithium, for example, will accept a charge rate that is equal to 100 percent of the rated capacity of the batteries (e.g., 100 amps into a 100-amp-hour battery) more-or-less up to 100 percent state of charge. In practical terms, with either technology the limiting factor in a DC system now becomes the output of whatever charging devices are available.

I conducted experiments on my brother Chris’ 40-foot Malo sailboat to better understand the implications of these technologies. These experiments were conducted in a typical off-the-grid cruising environment, gunkholing in the Bahamas. We installed a set of four Odyssey PC2250 TPPL batteries and wired them in parallel to produce a nominal capacity of 500 amp-hours at 12 volts. We replaced the 80-amp alternator on the Yanmar engine with a 120-amp Balmar alternator controlled by an external Balmar 614 voltage regulator. (Note that we chose TPPL over lithium because of the high cost of lithium as compared to TPPL, which, itself, is about a 30 percent more expensive than quality AGMs.)

|

|

The lower the current input rate, the higher the cost of battery charging per kilowatt hour while at anchor. |

Voltage regulation

The first operational task was to establish an appropriate charging regime for the TPPL batteries. This technology is too new for existing regulators to have a built-in program. The Balmar 614 was an excellent platform for our testing in as much as it has numerous user-settable parameters (via the ‘advanced’ programming mode) which enabled me to develop customized charging algorithms.

The European Union funded HYMAR (HYbrid MARine) project, of which I was the technical coordinator, conducted extensive destructive testing of TPPL batteries at the EnerSys factory in Wales (UK). Based on this testing, a preliminary conclusion is that in cycling applications the Odyssey and SBS batteries are more likely to suffer a loss of cycle life, and thus life expectancy, through undercharging than through overcharging. Another preliminary conclusion is that in order to optimize cycle life, the batteries need to be periodically pushed to a full state of charge (a ‘conditioning’ cycle) which, even with the TPPL technology, requires up to four hours at low charge acceptance rates, declining to as low as 100 milliamps per 100 Ah of battery capacity at the end of the cycle.

This latter target — 100 mA per 100 Ah of battery capacity — creates a problem not just in terms of the very low charge rates, but also because the traditional amperage-measuring shunts used in most popular battery monitoring systems cannot accurately measure at these levels. For example, a ‘typical’ shunt that creates a 200 mV drop at 200 amps current flow will see 1 mV (1/1,000th of a volt) drop per amp, and can measure reasonably accurately to maybe as low as an amp, but no lower. It would require a resolution of 0.1 mV (1/10,000th of a volt) to read 100 mA.

Given the goal of minimizing Chris’ engine run time for battery charging at anchor, I programmed the Balmar 614 regulator for aggressive charging based on modifying an existing flooded deep cycle program. And given the inadequate resolution of his amp measuring device, I built in a minimum four-hour absorption phase as a mechanism to maintain charging until the charge acceptance rate was down to the milliamp level. My programming relies on intermittent periods of extended motor sailing (for several hours) and infrequent dockside hook-ups (enabling the battery charger to be plugged in) to create the extended charging periods needed for the conditioning cycle.

Alternator heating

We knew that in any state of charge below even a moderately discharged state, the high charge acceptance rate of the TPPL batteries would drive the alternator to full output for an extended period of time. Even high output alternators rated for high temperature operation do not like this, and will potentially burn up, so we used the ‘belt load’ function in the Balmar regulator to limit the maximum alternator output to 80 percent (i.e., a nominal 96 amps).

|

|

Using a meter and a handheld probe, Calder determined that an internal sensor was cutting output when the alternator reached a temperature of 226° F. |

As expected, the alternator rapidly ramped up to 90+ amps and remained at this level. However, within 10 to 15 minutes the charge rate dropped in half for a couple of minutes and then ramped back up. Thereafter it cycled about 50 percent of the time at high output and 50 percent at half. I knew what was going on. The Balmar regulator has an alternator temperature sensing device which is factory set to 108° C (226° F). If this temperature is reached, it cuts the alternator’s output in half. A quick check with a multimeter and thermocouple confirmed that at high output the temperature was rapidly rising to the setpoint. It should be noted that the ambient temperature in the boat’s cabin was around 80° F, which is certainly not unusual for a boat in a warm or tropical climate.

The underlying problem here is the chronic inefficiency of alternators. At peak efficiency they are rarely much above 50 percent efficient, and over many parts of their operating cycle they are well below 50 percent efficient. Taking our alternator as an example, at 90 amps output and a charging voltage of 14 volts, the alternator is putting out 90 x 14 = 1,260 watts = 1.26 kW of power. At 50 percent efficiency, it is also generating 1.26 kW of heat, which has to be removed from the case in order to prevent the windings and diodes from frying. Regardless of their rating, without excellent heat dissipation high-output alternators cannot be run continuously at anywhere near their full rated output.

Heat issues are exacerbated by the need to muffle the sound of the engine. In common with many boatbuilders, Malo installs excellent sound insulation in its engine compartments, but one of the inevitable side effects is to limit the airflow through the engine and machinery spaces. Any alternators, more-or-less wherever they are mounted on the engine, end up in a cramped space close to the insulation.

Extra cooling

Chris has a factory-installed engine room blower on his boat, designed to suck heat out of the engine room. There is a passive four-inch duct from the aft end of the cockpit coaming into the engine room to allow air in. We added four-inch ducting to the blower’s inlet side and led this to a point directly behind the alternator so we could suck heat right off the back of the alternator. In spite of a lot of hot air coming out of the blower’s exhaust vent, the alternator still overheated in about the same time as before, which was puzzling. I contacted Balmar for their thoughts and found out that this alternator has dual fans — one at each end — which suck air in from the front and back and exhaust it out the sides. By installing the ducting behind the alternator, we were effectively stalling the air flow at this end of the alternator, exacerbating the heating issues!

|

|

Nada’s old 120-amp, 24-volt alternator alongside the new Balmar 97 EHD 195-amp, 24-volt alternator. A big difference in scale! |

We moved the ducting to a point where the blower sucked off the side of the alternator. From a cold start, the alternator now ran twice as long as previously before it reached the high temperature threshold, and then tripped to the reduced output level for about one-third of the time, returning to high output for two-thirds of the time. We made one final adjustment in the Balmar regulator, which was to raise the alternator’s high temperature threshold from 108° C to 114° C (237° F). Balmar states that this threshold can be raised to as high as 120° C (248° F) but we did not want to push the alternator to its limits. In any event, at 114° C, in an ambient cabin temperature of 80° F, and with the engine room blower sucking off the side of the alternator, the system now runs continuously without reaching the temperature threshold.

The net effect of these changes is to substantially reduce the engine run time for battery charging on this boat. Reduced engine run time translates directly into a lowered amortized cost of power, and an improved lifestyle. There is another hidden improvement here as well, in as much as the efficiency losses charging and discharging a TPPL battery are only around half of those with conventional lead-acid batteries, so more of the alternator’s output is put to useful work (or, to put it another way, it takes less engine run time at a given alternator output to put back a given amount of energy into the batteries). With lithium, these losses would be virtually non-existent.

Exploiting the potential

Even with the changes we made to Chris’ boat, we are only scratching the surface of the potential inherent in these new battery technologies. Given his nominal 500-amp-hour battery capacity, charging devices of up to 500 amps could be put to use (in fact, at a 50 percent state of charge the TPPL batteries can accept charging currents that are well above 100 percent of the battery’s rated capacity; lithium can easily accept 200 percent of rated capacity). These kinds of charge rates would dramatically reduce the engine run time and the amortized cost of power.

In practice, it is hard to find alternators with outputs greater than 200 amps at 12 volts, and with an output curve that is suitable for battery charging at anchor (it requires the alternator to be wound such that it achieves its rated output at relatively low rpms).

|

|

The initial Balmar 97 EHD installation is shown here. Calder discovered he could not maintain enough belt tension on the big alternator and later had to add an idler pulley to increase the belt wrap. |

Assuming we could run the alternator at its full rated output (in practice, we’ll never achieve this), at 200 amps and 14 volts the charge rate would be 2.8 kW = 3.6 hp, which, given 50 percent alternator inefficiencies, translates into a load on the engine of 7.2 hp (perhaps a bit higher with belt and other losses). The propulsion engine is still lightly loaded so its operation remains inherently inefficient. At full rated output a 500-amp alternator would get us to 7 kW (9.1 hp), placing a respectable load of close to 20 hp on the engine, but if this is a side load it will void most warranties!

In any alternator installation, so long as there is adequate space, a large frame alternator will invariably have better heat dissipation characteristics than the more typical small frame alternators. Beyond this, there will always be a conflict between providing effective cooling without compromising engine compartment sound shielding.

A much more efficient way to exploit the capabilities of these new batteries is by using a stand-alone DC generator. The electrical end of the generator will be more efficient than an alternator (some have peak efficiencies above 90 percent), and, with proper design, the load can be matched to the engine such that whenever the engine is running, it is always operating at, or close to, its peak efficiency. The net effect is a radical increase in the average charge rate and in the efficiency of the system, with a concomitant reduction in engine run hours and the amortized cost of power.

On my own boat, for the HYMAR experiments we had 12 100-Ah Odyssey batteries wired in series to give us 144v. This equated to a nominal 14.4-kWh battery bank (1,200 Ah at 12v). We had a 22-kW, 144v DC generator from Polar Power. At a 50 percent state of charge, the batteries drove the generator to full continuous output. We could put enough energy into the batteries in 15 minutes to run the boat at anchor for several days!

Deficit reduction

The measures we have taken on Chris’ boat represent an interim approach to reducing the energy deficit on this, and similar, boats. If the TPPL batteries and upgraded alternator and regulator are installed as original equipment, the cost differential over a conventional installation is not that great. If the boat spends any significant time battery charging at anchor, the cost will be quickly paid for in terms of reduced engine run time. Although lithium is considerably more expensive than TPPL on a kWh of capacity basis, if its improved performance can be fully exploited it will prove even more cost effective over the lifetime of the batteries.

A longer-term solution would redesign the DC system to fully exploit the high charge acceptance rates of these new battery technologies. The net result would be a radical reduction in the amortized cost of energy on boats, with greatly reduced engine run times for energy production on off-the-grid boats, and considerably more energy available.

————

Contributing editor Nigel Calder is a principal member of the EU Hybrid Marine Project and the author of Boatowner’s Mechanical and Electrical Manual.